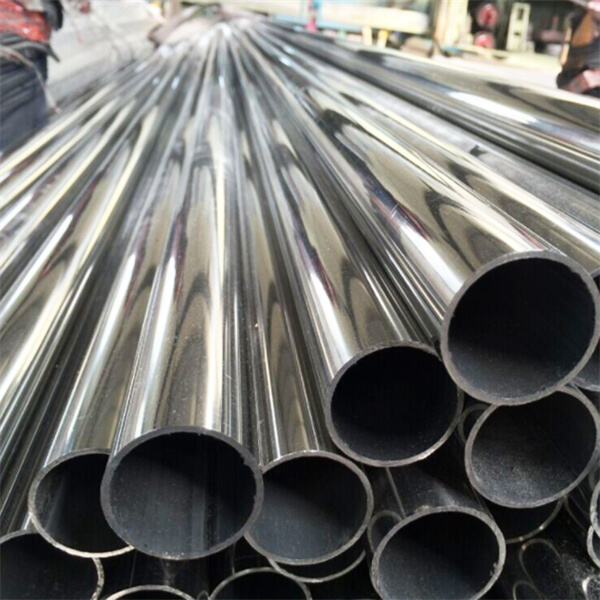

904L stainless steel pipe (00Cr20Ni25Mo4.5Cu) is an austenitic stainless steel with better corrosion resistance. Because of the addition of 1.5% copper, it also has excellent corrosion resistance against reducing acids such as sulfuric acid and phosphoric acid. In addition, It has low carbon properties for welding purposes.

| Product Name | 904L Stainless Steel Pipe | |

| Type | Steel Pipe | |

| Outer diameter | Round Tube | 4mm-200mm |

| Square Tube | 10*10mm-100*100mm | |

| Rectangular Tube | 10*20mm-50*100mm | |

| Wall Thickness | 0.6mm-6.0mm | |

| Length | 1-6 meters, Length can be customized | |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

| Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, No. 4. BA, etc. | |

| Scope of Application | Common applications for stainless steel pipes include food processing,Textile operations, Breweries, Water treatment plants, Oil and gas processing,Fertilizers and pesticides, Chemical applications, Construction, Pharmaceuticals, Auto parts, etc. | |

| Certificate | ISO, SGS, BV, etc. | |

| Production Technology | Hot Rolling, Cold Rolling | |

| Edge Processing | Edging, Trimming | |

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥ 520 | ≥ 275 | ≥55-60 | ≤183HB;≤ 100 HRB |

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(μohm.in) |

| 7.8 | 197 | 15.7 | 16.2 | 27 |

| C | Si | Mn | Cr | Ni | S | P |

| ≤ 0.15 | ≤ 0.75 | 5.50~7.50 | 16.00~18.00 | 3.50~5.50 | ≤ 0.03 | ≤ 0.06 |

904L stainless steel pipe has stronger corrosion resistance than other similar austenitic stainless steel pipes. The main reason is because of the addition of 1.5% copper element, especially for reducing acidic corrosion such as sulfuric acid and phosphoric acid. It has very high corrosion resistance, and at the same time it is easy to weld and process and has low carbon characteristics.