As the basic steel of the austenitic series, 304 stainless steel plate has excellent corrosion resistance, heat resistance, low temperature strength and mechanical properties. It does not harden after heat treatment and is almost non-magnetic. 304 stainless steel plates are widely used in industrial transportation pipelines such as petroleum, chemicals, medical, food, heat exchangers, etc. In addition, when the torsional strength and bending strength are the same, it is lighter than the weight, so it is also widely used in engineering structures.

| Materials: Grade (ASTM UNS) | 201,304,304L,321,316,316L,317L,347H,309S,310S,904L,2205,2507,254SMOS,32760,253MA,N08926,etc |

| Thickness | Cold rolled:0.4mm-3.0mm Hot rolled:3.0mm-100mm or as required |

| Length: | 2000mm, 2438mm, 3000mm, 5800mm, 6000mm,12000mm, etc |

| Width | 40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Standard: | ASTM,AISI,JIS,GB, DIN,EN |

| Surface: | BA,2B,NO.1,NO.4,4K,HL,8K |

| Application: | It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components.It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc. |

| Certification: | ISO, CE, EU, BIS |

| Technique: | Cold Rolled Hot Rolled |

| Edge: | Mill Edge Slit Edge |

Difference between 304 and 304L

| Difference | 304 | 304L |

| Properties | Austenitic basic steel grade, the most widely used;Excellent corrosion resistance and heat resistance;Excellent low temperature strength and mechanical properties;Single-phase austenite structure, no heat treatment hardening | Compare 304 Excellent corrosion resistance |

| Use | Category 1,2 tableware, exterior materials, building materials, automotive parts,Medical equipment, chemistry, food technology, fiber industry,ship parts | Equipment in the chemical, coal, and petroleum industries with high requirements for grain boundary corrosion resistance,Building materials, heat-resistant parts and parts difficult to heat treat |

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥480 | ≥177 | ≥ 40 | ≤ 187HB;≤ 90HRB;≤ 200HV |

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

| 7.99 | 193 | 16.0 | 16.2 | 74 |

| C | Si | Mn | Cr | Ni | S | P | Mo |

| ≤ 0.03 | ≤ 0.75 | ≤ 2.0 | 16.0~18.0 | 10.0~14.0 | ≤ 0.03 | ≤ 0.045 | 2.0~3.0 |

| Name | Surface | Features | Use |

| Original Surface | NO.1 | Silver white | Industrial tanks, chemical industry equipment, etc.,thicker by the mm-10.0mm of 3.0. Uses that do not require a surface gloss |

| Matte | |||

| Nlunt Surface | 2D | Slightly shiny silvery white | Used for deep drawing processing, such as automobile components, water pipes, etc.General materials, deep drawing materials |

| Fog Surface | 2B | Silver white with better gloss and flatness than 2D surface 0.39 micron roughness | Such as tableware, building materials, etc.After surface treatment to improve mechanical properties, almost all applications are satisfied. |

| Frosted Surface | NO.3 | Has a good gloss, with discontinuous rough | Used for building interior and exterior decoration materials,electrical products and kitchen equipment. |

| Frosted Surface | NO.4 | Has a better gloss, with discontinuous rough, stripes than NO. 3 fine | Used for baths, building interior and exterior decoration materials,electrical products, kitchen equipment and food equipment. |

| Frosted Surface | NO.240 | Has a better gloss, with discontinuous rough, stripes than NO. 4 fine | Used for bathroom, building interior and exterior decoration materials,electrical products, kitchen equipment and food equipment. |

| Frosted Surface | NO.320 | Has a good gloss, with discontinuous rough | Building Materials, Kitchenware |

| Frosted Surface | NO.400 | Has a good gloss, with discontinuous rough | Building materials, kitchen utensils, food equipment, etc. |

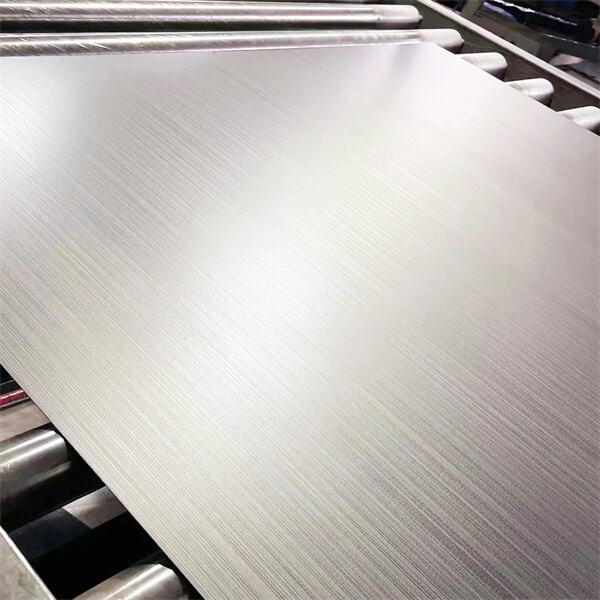

| Brushed Surface | HL | Silver gray with hairline stripes on the 2D or 2B product with the appropriate particle size abrasive material polished to make the surface continuous grinding pattern | Mainly used in architectural decoration, elevators, building doors, panels, etc. |

| Bright Surface | BA | Excellent surface gloss with high reflectivity | Used for home appliances, mirrors, kitchen equipment, decorative materials, etc. |

| Mirror | 6K | Not much worse than a mirror. | Mirror, trim panel |

| Mirror | 8K | Like a mirror. | Mirror, trim panel |